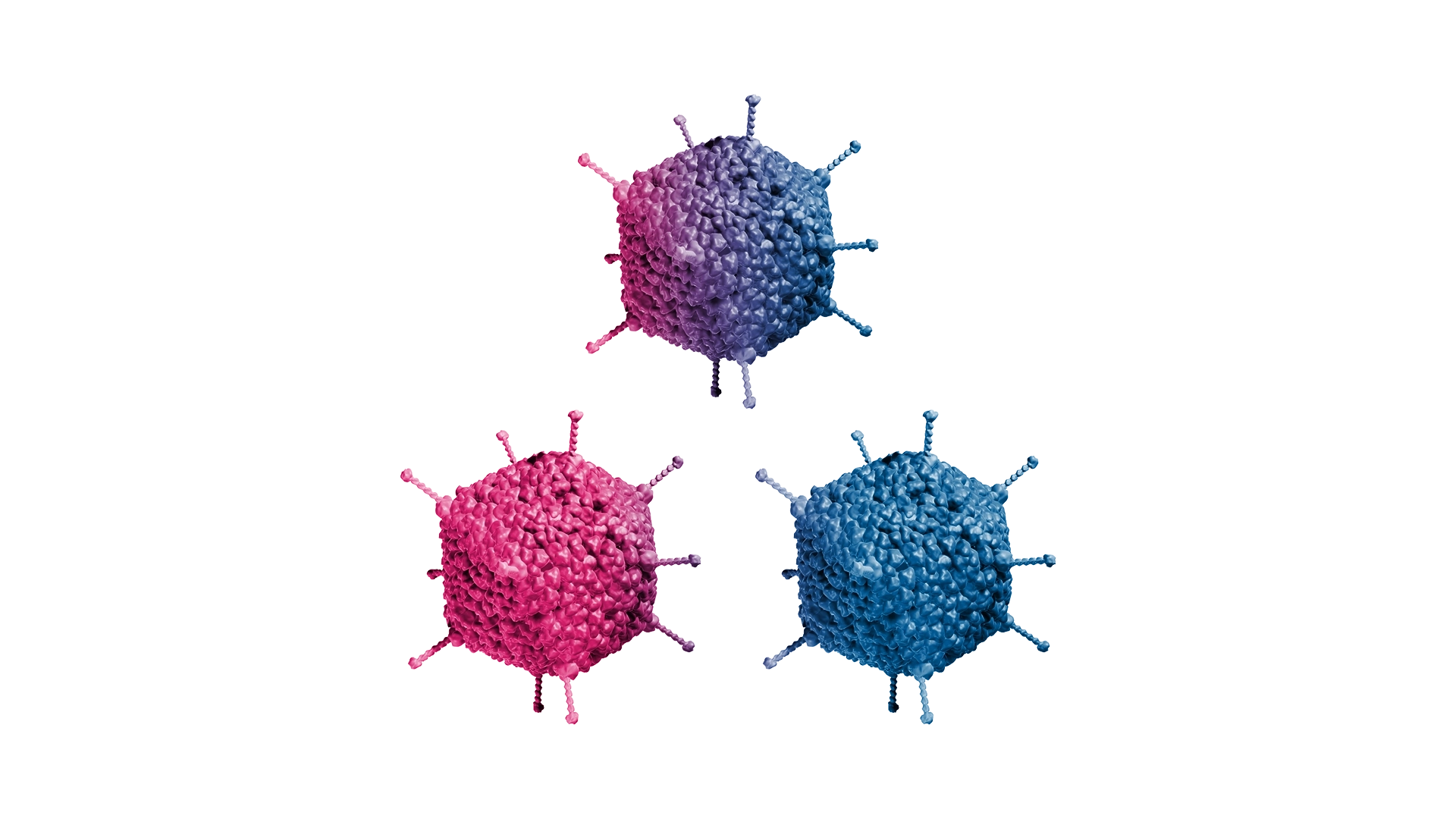

Viral Vector Services

Adenovirus Upstream Processes

We assist with selecting the producer cell line and culture type based on the adenovirus serotype and other factors and needs.

Our partnerships can provide access to the most recent technologies and production platforms.

The adenovirus vector upstream processes include:

- Mammalian cell culture, e.g., HEK293, or Sf9 insect cells

- Transfection with plasmids or transduction with baculovirus, depending on the selected approach and serotype

- Cell harvest and lysis

- Analysis of harvest

Suspension cell culture

Adenovirus vector production in suspension cultures allows for easy upscaling and reduces process costs. Producer cell lines such as HEK293 cells can be adapted to suspension culture and can grow in serum-free media, enhancing the safety profile.

For small-scale suspension cultures, shake flasks with various capacities can be used. For large-scale suspension cultures, bioreactor options for single-use stirred-tank bioreactors with a GMP volume of up to 200 L are available. The cultivation method applied is project-dependent, with options including perfusion, fed-batch, or batch cultivation. Suspension cell culture platforms and harvesting options:

Adherent cell culture

Adenovirus vectors can be produced using adherent cell cultures in T-flasks or multilayer vessels such as hyperflasks or cell stacks. Alternatively, adherent cell cultures can be conducted in bioreactors, including packed-bed bioreactors or single-use systems with microcarriers. While adherent cultures necessitate tissue-culture-treated vessels and repeated passaging, they offer the advantage of easy visual inspection under a microscope.

With you all the way…

together, making advanced biologics, and tomorrow’s life-transforming therapies.

We deliver unparalleled end-to-end development and manufacturing services for all protein expression systems and viral vectors, both for Drug Substances and Drug Products, from pre-clinical to clinical development and commercial phases.

We support our customers wherever they are on their journey, from early-stage development to commercialization. We are passionate, precise, and always close, together, making advanced biologics and tomorrow’s life-transforming therapies.

Pre-Clinical

Phase I

Phase II

Phase III

Commercial